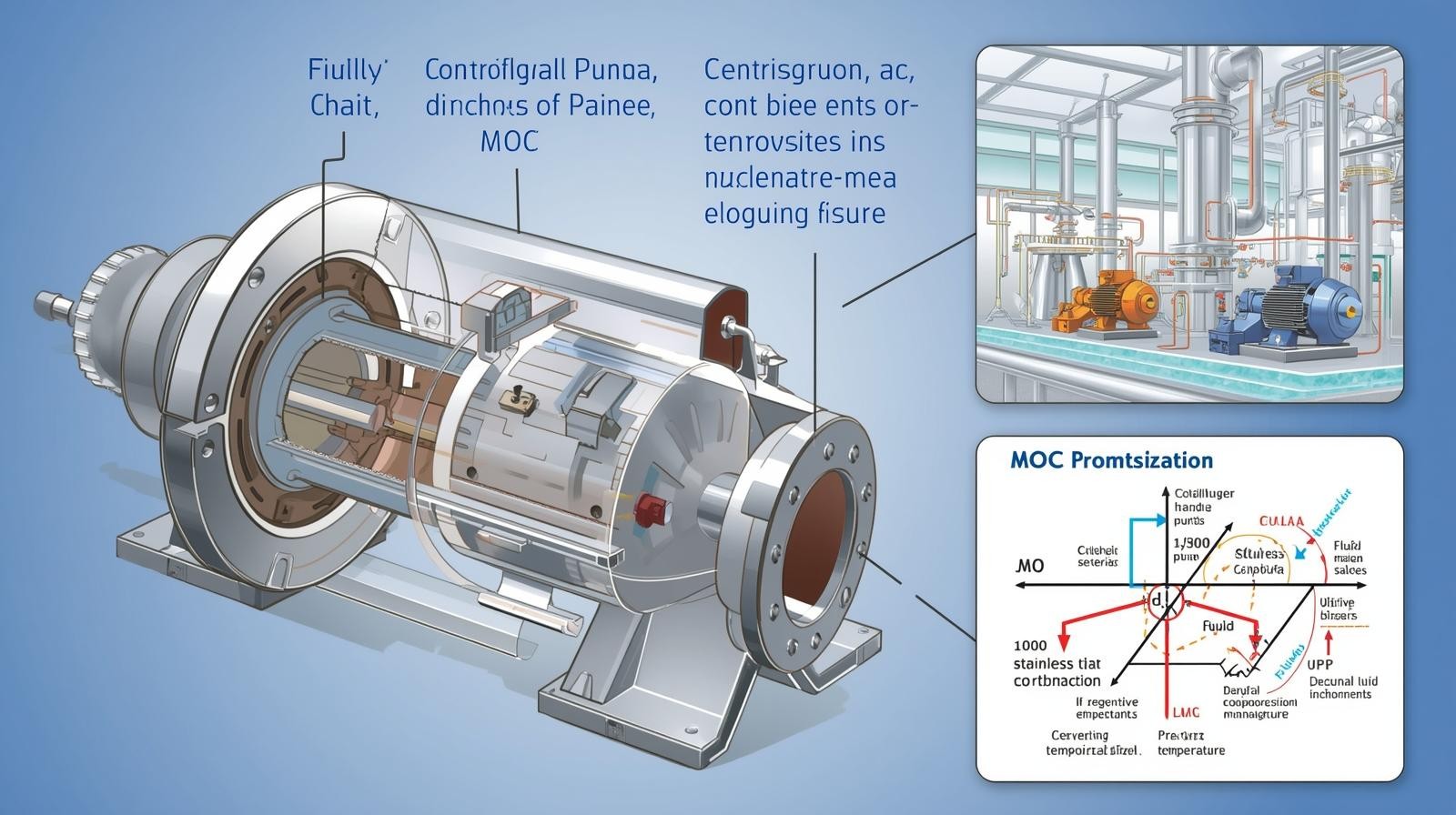

The Ultimate Guide to Centrifugal Pump Materials of Construction (MOC)

The Materials of Construction (MOC) selection for Centrifugal Pumps dictates the pump’s lifespan and performance, making it a critical engineering decision. The primary challenge is balancing corrosion resistance, abrasion handling, and cost. While Cast Iron is suitable for general, non-corrosive fluids, Stainless Steel (316 SS) is the industry standard for chemical and high-corrosion applications. Non-metals are necessary for highly aggressive chemicals. Always base your final choice on the full analysis of the fluid’s chemical properties and operating temperatures. Regular maintenance and avoiding conditions like centrifugal pump cavitation are essential for protecting the MOC integrity.

1. Introduction: The Critical Role of MOC in Pump Reliability

Centrifugal Pumps are the workhorses of fluid transfer across virtually all industrial sectors. The integrity and longevity of these machines hinge almost entirely upon the Materials of Construction (MOC) used for their core centrifugal pump parts. Choosing the wrong material can lead to premature wear, catastrophic failure, and extensive downtime, making the MOC decision a complex balance of chemistry, metallurgy, and cost.

This comprehensive guide will detail the classifications, critical selection criteria, and strategic considerations required to select the optimal MOC before you Choose a Centrifugal Pump for your system.

2. Primary Classifications of Centrifugal Pump Materials

The components of any pump, including the casing, impeller, shaft, and sealing mechanism, require an MOC tailored to its specific function and exposure to the pumped fluid. These materials are generally grouped into three categories:

2.1. Ferrous Metals: The Cost-Effective Base

These materials are the default choice for general service where high corrosion resistance is secondary to strength and cost.

- Cast Iron (CI): The most common and economical choice. CI offers good compressive strength and decent abrasion resistance, making it suitable for water, sewage, and non-corrosive fluid transfer. However, it fails quickly in acidic or high-chloride environments.

- Carbon Steel (CS): Provides higher tensile strength and temperature tolerance than Cast Iron, often used for high-pressure systems in the oil and gas industries. Its major drawback is its poor resistance to water-based corrosion (rusting).

2.2. Non-Ferrous and Corrosion-Resistant Alloys

This critical group is selected when fluid chemistry demands superior protection against chemical attack.

- Stainless Steel (SS): The industry benchmark for many corrosive applications.

- 304 SS: A basic austenitic grade suitable for food, beverage, and mild chemical services.

- 316 SS: The preferred grade, containing Molybdenum for significantly enhanced resistance to pitting and crevice corrosion, particularly in environments with chlorides.

- Bronze and Brass: Excellent options for handling non-chlorinated saltwater and seawater due to their inherent resistance to biofouling and good anti-seizure characteristics.

- Specialty Alloys (Duplex, Hastelloy, Titanium): Used for extremely aggressive, high-temperature, or high-pressure services.

#### Duplex Stainless Steel (DSS)

DSS alloys feature a mixed ferrite-austenite microstructure, offering superior strength (allowing for thinner components) and significantly better resistance to stress-corrosion cracking than standard austenitic SS. They are crucial for highly stressed equipment, like certain type of Centrifugal Pumps used in offshore applications.

#### Nickel Alloys (Hastelloy and Inconel)

These high-nickel, chromium, and molybdenum alloys (like Hastelloy) provide near-universal resistance to concentrated acids (sulfuric, hydrochloric) and other aggressive chemicals, often seen in critical chemical processing units.

#### Titanium

Titanium offers exceptional resistance to oxidizing acids and is virtually immune to attack from chloride solutions, making it an excellent, albeit expensive, material for chemical Centrifugal Pumps and extreme seawater services.

2.3. Non-Metallic Materials (Plastics and Polymers)

When a fluid is too aggressive for metals or purity is paramount, non-metals are used, often as linings or for the entire pump construction.

- Fluoropolymers (PTFE, PFA): Provide the highest level of chemical inertness, resisting almost all industrial chemicals and solvents, crucial for chemical dosing and laboratory applications.

- Polypropylene and PVC: Cost-effective choices for transferring less concentrated chemicals at ambient temperatures.

3. Key Determinants in MOC Selection

Matching the MOC to the intended service requires a rigorous evaluation of the operating environment:

3.1. 🔬 Fluid Chemistry and Corrosion Risks

The chemical properties of the fluid are paramount. Factors include:

- pH and Concentration: Determines the type and rate of chemical attack.

- Chloride Content: High chlorides necessitate the use of Molybdenum-containing alloys (like 316 SS) or specialty alloys to prevent pitting.

3.2. ⚙️ Abrasion and Solids Content

The presence of hard solids (e.g., sand or metallic particles) in the fluid causes abrasive wear, leading to rapid deterioration of the centrifugal pump parts. In these scenarios, highly wear-resistant materials like hardened Cast Iron, high-chrome alloys, or rubber linings are necessary.

3.3. 🌡️ Operating Temperature and Pressure

These factors influence material strength and corrosion rate. High temperatures can accelerate chemical reactions, decrease the yield strength of metals, and seriously degrade the performance of polymers.

4. Maintenance and Operational Longevity

Selecting the correct MOC is only the first step. To achieve maximum lifecycle value, proper operation and maintenance are non-negotiable.

4.1. Installation and Priming

Proper setup, starting with the procedure to Install a Centrifugal Pump System, ensures that mechanical stress is minimized. Furthermore, correctly executing how to prime a centrifugal pump prevents dry running, which can rapidly damage seals and wear rings regardless of MOC.

4.2. Monitoring and Troubleshooting

Regular monitoring of pump performance against its ideal Centrifugal Pump Curves helps detect operational drift early. If deviations occur, prompt centrifugal pump troubleshooting can prevent damage that compromises the integrity of the material structure. Regular application of the Centrifugal Pump Maintenance plan is also essential for extending the life of all components.

5. Conclusion

The selection of Centrifugal Pump Materials of Construction is a fundamental engineering task that dictates a pump’s fitness for purpose. The ultimate goal is to minimize lifecycle cost by choosing an MOC that can withstand the chemical and physical demands of the fluid and environment. While cost-effective choices like Cast Iron suffice for general service, aggressive media inevitably demand the superior resistance of alloys like SS 316, Duplex, or specialized non-metals. A well-chosen MOC, combined with diligent maintenance and operation, guarantees industrial reliability.