Centrifugal Pump Cavitation: The Complete Prevention Guide for Industrial Operations

That unmistakable sound of marbles rattling inside your equipment isn’t just annoying—it’s the sound of your pump crying for help. Centrifugal pump cavitation represents one of the most destructive forces in industrial pumping systems, capable of destroying impellers, wrecking bearings, and creating costly downtime. For maintenance engineers, plant managers, and operational staff, understanding centrifugal pump cavitation isn’t just technical knowledge—it’s essential for protecting your bottom line. This comprehensive guide delivers everything you need to understand, identify, and prevent centrifugal pump cavitation in your operations.

Understanding Centrifugal Pump Cavitation: The Basic Principles

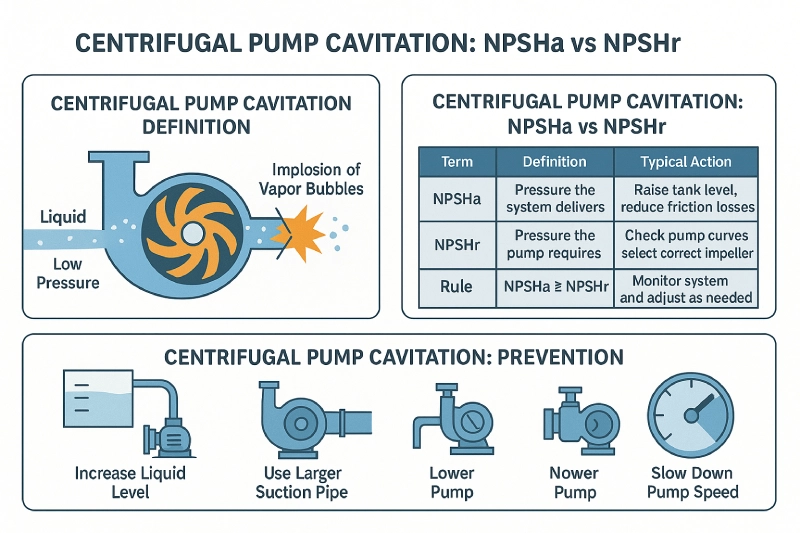

Centrifugal pump cavitation occurs when vapor bubbles form and collapse violently within a pumping system. When fluid enters the pump, pressure at the impeller eye can drop below the liquid’s vapor pressure, causing the liquid to “boil” at ambient temperature and form vapor pockets. These bubbles then travel into higher-pressure zones where they implode with tremendous force—a process that hammers metal surfaces and destroys pump efficiency. Understanding this fundamental mechanism is the first step in combating centrifugal pump cavitation.

The Simple Science Behind Centrifugal Pump Cavitation

The physics of centrifugal pump cavitation revolves around pressure differentials and phase changes. As liquid accelerates into the impeller, local pressure drops can create vacuum pockets where vapor bubbles nucleate. When these bubbles collapse, they release micro-jets of energy that strike metal surfaces at supersonic speeds. This implosion process generates the characteristic noise and vibration associated with centrifugal pump cavitation while systematically eroding pump components.

Identifying the Root Causes of Centrifugal Pump Cavitation

The primary driver of centrifugal pump cavitation is always insufficient pressure at the pump suction. This pressure deficit creates a vacuum that flashes liquid into vapor, initiating the destructive cavitation cycle. Common scenarios that trigger centrifugal pump cavitation include:

- Restricted flow from clogged suction strainers or filters

- Undersized suction piping creating excessive friction losses

- Pump operation too far from its Best Efficiency Point (BEP)

- Partially closed suction valves or other flow restrictions

- Elevated fluid temperatures increasing vapor pressure

Each of these conditions contributes to centrifugal pump cavitation by disrupting the balance between system supply and pump demand.

Mastering NPSH to Combat Centrifugal Pump Cavitation

The most critical concept in preventing centrifugal pump cavitation is Net Positive Suction Head (NPSH). This two-part measurement determines whether your system can deliver sufficient pressure to avoid vaporization.

NPSHa vs NPSHr: The Centrifugal Pump Cavitation Battle

NPSH Available (NPSHa) represents the pressure your system delivers to the pump suction, calculated from static head, atmospheric pressure, and friction losses minus vapor pressure. NPSH Required (NPSHr) is the minimum pressure the pump needs to avoid centrifugal pump cavitation, as determined by manufacturer testing.

| Parameter | Definition | Control Factors | Improvement Strategies |

| NPSHa | System-supplied pressure | Tank elevation, piping design, fluid temperature | Raise supply tank, increase pipe diameter, clean filters |

| NPSHr | Pump-required pressure | Impeller design, operating speed, flow rate | Select low-NPSH pump, reduce speed, operate at BEP |

The Golden Rule: NPSHa must exceed NPSHr with a safety margin of at least 1 meter or 10-20% to prevent centrifugal pump cavitation.

Vapor Pressure’s Role in Centrifugal Pump Cavitation

Vapor pressure significantly impacts centrifugal pump cavitation susceptibility. As temperature rises, vapor pressure increases, requiring higher suction pressure to maintain liquid state. This explains why hot water applications experience centrifugal pump cavitation more readily than cold water systems. Always calculate NPSHa using actual operating temperatures to accurately assess centrifugal pump cavitation risk.

Recognizing the Signs of Centrifugal Pump Cavitation

Early detection of centrifugal pump cavitation symptoms can prevent catastrophic damage. The most reliable indicators involve multiple senses:

Audible and Visual Signs of Centrifugal Pump Cavitation

The characteristic sound of centrifugal pump cavitation resembles marbles or gravel rattling inside the pump casing. This unmistakable noise results from vapor bubbles collapsing near metal surfaces. Visually, discharge pressure gauges may show fluctuation or decay, while flow meters indicate reduced capacity. These sensory clues provide the first warning of developing centrifugal pump cavitation.

Performance Indicators of Centrifugal Pump Cavitation

Beyond audible cues, centrifugal pump cavitation manifests through measurable performance degradation. Efficiency drops as vapor bubbles disrupt smooth energy transfer from impeller to fluid. Power consumption may become erratic, and vibration levels increase dramatically. Monitoring these parameters helps identify centrifugal pump cavitation before severe damage occurs.

Assessing Damage from Centrifugal Pump Cavitation

The destructive consequences of centrifugal pump cavitation extend far beyond noise and vibration. Understanding the potential damage highlights why prevention is crucial.

Mechanical Damage from Centrifugal Pump Cavitation

The implosive nature of centrifugal pump cavitation causes progressive material loss through pitting erosion. Impeller vanes develop characteristic craters that destroy hydraulic efficiency. Severe cases of centrifugal pump cavitation can crack impellers or wear through volute casings, requiring complete replacement of these expensive components.

Systemic Consequences of Centrifugal Pump Cavitation

Beyond direct mechanical damage, centrifugal pump cavitation triggers secondary failures throughout the system. The high-frequency vibrations hammer bearings and mechanical seals, dramatically shortening their service life. This vibration can also transmit through piping systems, creating fatigue cracks and joint failures far from the pump itself.

Implementing Centrifugal Pump Cavitation Prevention Strategies

Proactive prevention represents the most cost-effective approach to managing centrifugal pump cavitation. These strategies address both system design and operational practices.

System Modifications to Prevent Centrifugal Pump Cavitation

Increasing NPSHa provides the most reliable defense against centrifugal pump cavitation. Practical approaches include:

- Elevating supply tanks to increase static head

- Upsizing suction piping to reduce friction losses

- Simplifying suction layouts by eliminating unnecessary fittings

- Installing suction boosters for challenging applications

Each modification directly addresses the pressure deficit that causes centrifugal pump cavitation.

Pump Selection and Operation to Avoid Centrifugal Pump Cavitation

Proper pump selection and operation significantly reduce centrifugal pump cavitation risk. Strategic approaches include:

- Choosing pumps with low NPSH requirements for challenging applications

- Using variable frequency drives to control pump speed

- Operating pumps near their Best Efficiency Point (BEP)

- Implementing multi-stage pumps for high-head applications

Our guide on How to Choose a Centrifugal Pump provides detailed selection criteria to avoid centrifugal pump cavitation.

Centrifugal Pump Cavitation Troubleshooting Protocol

When centrifugal pump cavitation symptoms appear, this systematic approach identifies and resolves the underlying cause:

Immediate Actions for Suspected Centrifugal Pump Cavitation

- Check suction valve position (ensure fully open)

- Verify supply tank level adequacy

- Inspect suction strainers for blockage

- Listen for characteristic cavitation noise

Intermediate Investigation of Centrifugal Pump Cavitation

- Calculate current NPSHa versus pump NPSHr

- Review pump operation relative to BEP using Centrifugal Pump Curves

- Check for air leakage on suction side

- Verify fluid properties and temperature

Comprehensive Resolution of Centrifugal Pump Cavitation

- Implement system modifications to increase NPSHa

- Consider pump replacement or modification for persistent issues

- Establish monitoring protocols for early detection

- Document lessons learned to prevent recurrence

For ongoing maintenance to prevent centrifugal pump cavitation, follow our Centrifugal Pump Maintenance checklist.

Installation Best Practices to Prevent Centrifugal Pump Cavitation

Proper installation creates the foundation for centrifugal pump cavitation-free operation. Key principles include:

- Designing suction piping with minimal length and maximum diameter

- Using gradual elbows instead of sharp turns

- Ensuring proper alignment to prevent strain-induced distortion

- Following manufacturer guidelines for minimum submergence

Our comprehensive guide to Install a Centrifugal Pump System details these critical installation practices to avoid centrifugal pump cavitation.

Advanced Solutions for Persistent Centrifugal Pump Cavitation

When conventional approaches fail to resolve centrifugal pump cavitation, these advanced solutions provide alternatives:

- Suction Inducers: Specialized pre-impellers that gradually increase pressure

- Double-Suction Impellers: Balanced designs that reduce inlet velocity

- VFD Control: Precise speed adjustment to match system requirements

- System Modeling: Computer simulation to identify and resolve pressure deficits

Conclusion: Mastering Centrifugal Pump Cavitation Prevention

Centrifugal pump cavitation represents a solvable challenge through proper understanding, system design, and operational practices. By recognizing the symptoms, understanding NPSH principles, and implementing proactive prevention strategies, engineers can eliminate the destructive consequences of centrifugal pump cavitation. Remember that prevention always costs less than repair—investing in proper system design and maintenance protocols pays dividends through extended equipment life and reduced downtime. For reliable equipment designed to minimize centrifugal pump cavitation risk, explore our range of Centrifugal Pumps engineered for performance and durability.

Frequently Asked Questions About Centrifugal Pump Cavitation

Q: What exactly is centrifugal pump cavitation in simple terms?

A: Centrifugal pump cavitation occurs when liquid vaporizes inside a pump due to low pressure, then implodes when reaching high-pressure areas. These implosions create shockwaves that damage pump internals and cause noise and vibration.

Q: How can I quickly identify centrifugal pump cavitation by sound?

A: Centrifugal pump cavitation produces a distinctive rattling or cracking noise often described as “marbles in a can.” This sound differs significantly from normal pump operation and usually indicates immediate action is required.

Q: What’s the most effective way to stop centrifugal pump cavitation?

A: The most reliable method to stop centrifugal pump cavitation is to increase NPSHa by raising liquid level, cleaning suction filters, or reducing suction line losses. Alternatively, reducing NPSHr through speed control or pump replacement can also resolve the issue.

Q: Can centrifugal pump cavitation damage be repaired?

A: Minor pitting from centrifugal pump cavitation can sometimes be repaired by welding and reshaping, but severely damaged impellers typically require replacement. The surrounding system must be corrected to prevent recurring centrifugal pump cavitation.

Q: How does temperature affect centrifugal pump cavitation risk?

A: Higher temperatures increase vapor pressure, making liquids more prone to vaporization and therefore increasing centrifugal pump cavitation risk. Hot fluid applications require greater NPSHa margins to prevent centrifugal pump cavitation.

Q: Where can I find replacement parts for pumps damaged by centrifugal pump cavitation?

A: Genuine centrifugal pump parts ensure proper fit and performance restoration after centrifugal pump cavitation damage. For persistent issues, consult our centrifugal pump troubleshooting guide.