A Complete Guide to Centrifugal Pump Parts & Functions

Centrifugal pumps are the workhorses of countless industries, from water supply and HVAC to chemical processing and oil & gas. Their reliable operation hinges on a precise interplay of mechanical components. Understanding these centrifugal pump parts is not just for engineers; it’s essential for operators, maintenance technicians, and procurement specialists to ensure efficiency, prevent failure, and reduce downtime.

This definitive guide will dissect a centrifugal pump, explaining the function, importance, and common issues associated with each critical component.

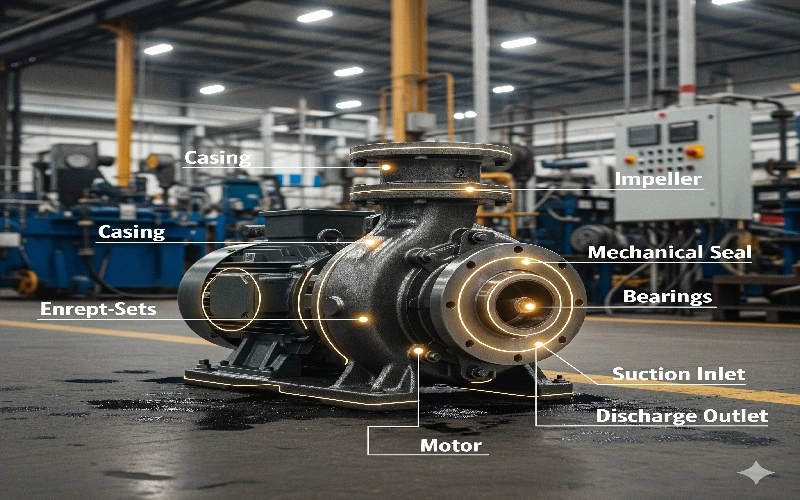

The 7 Main Components of a Centrifugal Pump

At its core, a centrifugal pump converts rotational kinetic energy from an engine or motor into hydrodynamic energy to move fluid. This process is achieved through several key parts.

1. Impeller: The Heart of the Pump

The impeller is the single most important rotating component that transfers energy from the motor to the fluid. It consists of a series of curved vanes that accelerate the fluid radially outward by centrifugal force.

Types of Impellers:

- Open Impeller: Vanes are open on both sides. Best for fluids with suspended solids but less efficient.

- Semi-Open Impeller: Has a back wall (shroud). A balance between efficiency and clog resistance.

- Closed Impeller: Vanes are enclosed between two shrouds. Most efficient for clean liquids but prone to clogging.

Experience Tip: Impeller erosion or corrosion is a leading cause of performance drop. Material selection (e.g., stainless steel, cast iron, or specialty alloys) is critical based on the pumped fluid.

2. Casing: The Pressure Containment Vessel

The casing is the outer shell of the pump that contains the liquid and directs it to the discharge point. It is designed to convert the high-velocity fluid from the impeller into steady flow with higher pressure.

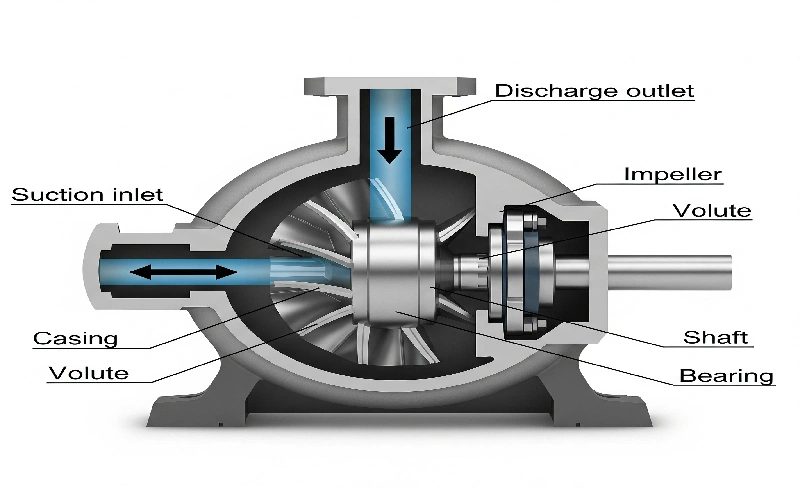

Volute vs. Casing: Often used interchangeably, but technically, the volute is the specific spiral-shaped section of the casing that collects the fluid. Its cross-sectional area increases towards the discharge nozzle, which efficiently converts velocity into pressure. A diffuser casing (or turbine casing) uses fixed guide vanes surrounding the impeller to achieve this pressure conversion and is often found in multi-stage pumps for higher efficiency.

3. Shaft and Shaft Sleeve: The Rotating Assembly

- Shaft: The steel rod that transmits torque from the motor to the impeller. It must be robust to withstand torsional and bending stresses.

- Shaft Sleeve: A removable cylindrical sleeve that protects the shaft from wear, corrosion, and erosion at the packing or seal areas. It is a sacrificial part, making maintenance cheaper and easier than replacing the entire shaft.

4. Mechanical Seal: The Leakage Preventer

This critical component seals the point where the shaft enters the casing, preventing the pumped fluid from leaking out. It consists of two primary faces—one rotating with the shaft and one stationary—that are lapped perfectly flat to create a tight seal.

Why it Matters: Gland packing (an older method) always has some leakage. Modern mechanical seals are designed for zero leakage, essential for handling hazardous, expensive, or volatile fluids.

5. Bearings: The Support System

Bearings constrain the radial and axial movement of the shaft, allowing it to rotate smoothly with minimal friction. They absorb the radial and axial loads imposed by the impeller.

- Radial Bearings: Support the radial loads (perpendicular to the shaft).

- Thrust Bearings: Support the axial loads (parallel to the shaft), which are caused by the hydraulic forces inside the pump.

Experience Tip: Bearing failure is one of the most common causes of pump shutdown. Proper lubrication and monitoring for overheating and vibration are paramount.

6. Wear Rings: The Efficiency Savers

These are renewable rings installed on the casing and/or the impeller that create a tight, controlled running clearance. This minimizes internal fluid recirculation from the high-pressure discharge side back to the low-pressure suction side.

What is a pump wear ring for? Its sole purpose is to protect the far more expensive impeller and casing from wear. As the clearance increases due to erosion, pump efficiency drops. When efficiency falls below acceptable levels, you simply replace the inexpensive wear rings instead of the entire impeller or casing.

7. Coupling and Baseplate: The Foundation

- Coupling: Connects the pump shaft directly to the driver (motor) shaft, ensuring efficient power transmission. Proper alignment is crucial; misalignment is a major source of vibration and premature failure of bearings and mechanical seals.

- Baseplate: The sturdy metal platform onto which both the pump and motor are mounted. It ensures the unit remains rigid and correctly aligned under operational stresses and temperature changes.

Centrifugal Pump Part Diagram

The diagram below illustrates how all these essential pump components integrate to form a fully functional unit.

Frequently Asked Questions (FAQs)

What are the main components of a centrifugal pump?

The seven main components are: the Impeller, Casing (Volute), Shaft, Mechanical Seal, Bearings, Wear Rings, and the Coupling. Each plays a vital role in moving fluid efficiently and reliably.

What is the most important part of a centrifugal pump?

While all parts are crucial, the impeller is often considered the most important. It is the primary component that adds energy to the fluid. Without it, there is no centrifugal force to create flow and pressure. Damage to the impeller directly and significantly impacts the pump’s performance.

What is a pump wear ring for?

Wear rings are sacrificial components designed to protect the main impeller and casing from wear. They maintain a small clearance to minimize internal leakage and maximize efficiency. When this clearance widens over time, replacing the wear rings restores efficiency and avoids the much higher cost of replacing the impeller or casing.

What is the difference between a volute and a casing?

The casing is the general term for the pump’s outer pressure boundary. The volute is a specific part of that casing—the spiral-shaped, funnel-like channel that captures the fluid discharged from the impeller and efficiently converts its velocity into pressure. Not all casings are volutes (e.g., diffuser casings), but a volute is always part of a casing.

Conclusion: Reliability Through Understanding

Knowing the function and interplay of centrifugal pump parts—from the powerful impeller to the sacrificial wear rings—is the first step toward proactive maintenance and operational excellence. By monitoring these pump components and understanding their failure modes, you can significantly extend the life of your equipment, reduce energy costs, and prevent unplanned downtime.

Ready to See These Parts in Action? Whether you’re specifying a new pump or maintaining an existing one, choosing the right equipment is critical. Explore our extensive range of reliable and efficient Centrifugal Pumps designed for a wide array of applications and built with quality components for long-lasting performance.