How to Prime a Centrifugal Pump: The Ultimate Safe and Effective Guide

I’ll never forget my first hard lesson in how to prime a centrifugal pump. It was a rushed startup on a hot summer day. The pump hummed and strained, but not a drop of water came out. My mentor shook his head and said, “Son, that pump isn’t broken. It’s thirsty and full of air.” That costly mistake (a destroyed impeller and a day of downtime) taught me that priming a centrifugal pump isn’t just a step in a manual; it’s the fundamental act of breathing life into your equipment.

If you’ve ever faced that frustrating “whirring” sound of a pump running dry, you’re in the right place. This guide merges years of hands-on experience with clear, practical steps to ensure you know exactly how to prime a centrifugal pump safely and effectively every single time.

What Does It Mean to Prime a Centrifugal Pump?

Let’s demystify the core concept. What does it mean to prime a centrifugal pump?

Imagine trying to drink a thick milkshake through a straw. You first suck the air out, creating a vacuum that draws the liquid up. If there’s a hole in the straw, you can’t create that suction.

A centrifugal pump operates on a similar principle. The impeller spins at high speeds, flinging fluid outward to create a low-pressure zone at its center. This low pressure allows the higher atmospheric pressure to push more liquid into the pump. However, air is far less dense than liquid. If the pump casing and suction line are full of air, the impeller spins uselessly, unable to create the pressure difference needed to draw liquid in.

Therefore, the pump priming process is the act of manually filling the pump casing and suction line with liquid, pushing all the air out. This creates a sealed, liquid-filled environment, enabling the pump to generate suction. It’s the equivalent of filling your straw with milkshake before you start drinking.

Why Learning How to Prime a Centrifugal Pump is Non-Negotiable

Understanding how to prime a centrifugal pump is critical because these pumps are not self-priming by nature. They depend on a liquid-filled environment to operate correctly. When air is trapped inside, you get a loss of prime, and the impeller simply churns air—a condition known as dry running.

Skipping this step is a recipe for disaster. Here’s what happens during dry running:

- No Flow: The most immediate sign. The pump runs but moves no fluid.

- Overheating: The pumped liquid acts as a coolant. Without it, internal components like the mechanical seal overheat and can crack within minutes.

- Catastrophic Damage: The result is often warped, seized, or shattered components, leading to complete pump failure and costly repairs. This is a common issue we address in our centrifugal pump troubleshooting guide.

Do All Centrifugal Pumps Need Priming?

This is a vital question when you’re planning to how to prime a centrifugal pump. The answer is: most do, but not all.

Almost all standard centrifugal pumps that operate with a suction lift (where the fluid source is below the pump) require manual priming. The only exceptions are specially designed self-priming centrifugal pumps, which can evacuate air from the suction side automatically after startup. If you want to avoid the priming process, consider this when you Choose a Centrifugal Pump.

The Essential Pre-Check Before You How to Prime a Centrifugal Pump

Before you begin the pump priming process, a quick pre-check can save you from failure:

- Inspect the Suction Line: Look for leaks or blockages. Even a tiny air leak can cause a loss of prime.

- Check Valves: Ensure the foot valve (at the bottom of the suction line) or check valve is installed and functioning to prevent liquid from draining back.

- Verify Valve Positions: Make sure all necessary valves are open, especially the vent valve.

- Confirm Cleanliness: Ensure the pump casing and suction pipe are free of debris.

- Review Performance Curves: Verify your system design, including suction lift, aligns with the pump’s Centrifugal Pump Curves.

Your Step-by-Step Guide on How to Prime a Centrifugal Pump Manually

Here is the combined, field-tested method for manually how to prime a centrifugal pump. Always consult your pump’s manual and wear appropriate PPE before starting.

Tools You’ll Need:

- A funnel or filling pot

- The correct priming fluid (usually the same as you’re pumping)

- Wrenches

- Rags

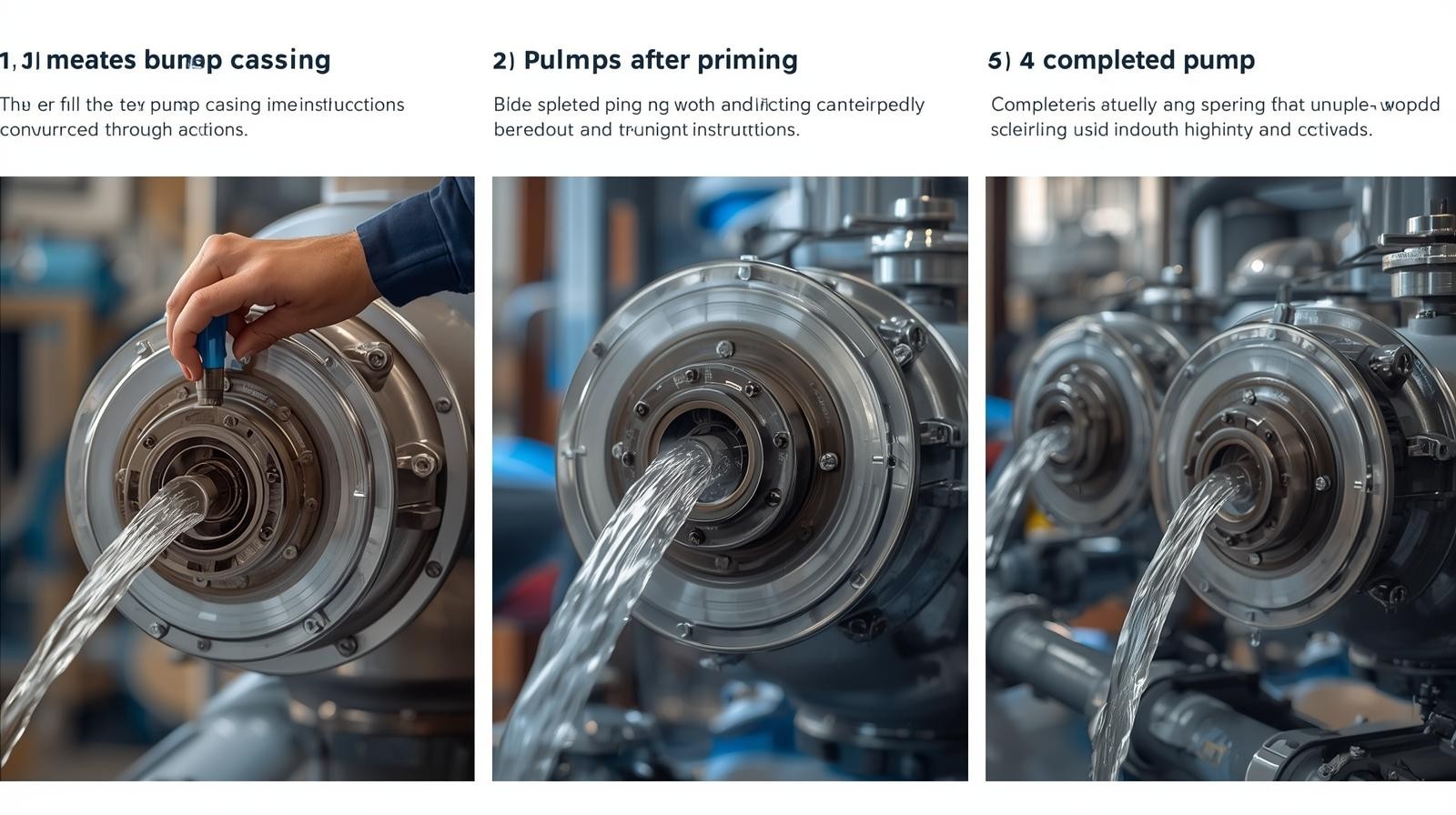

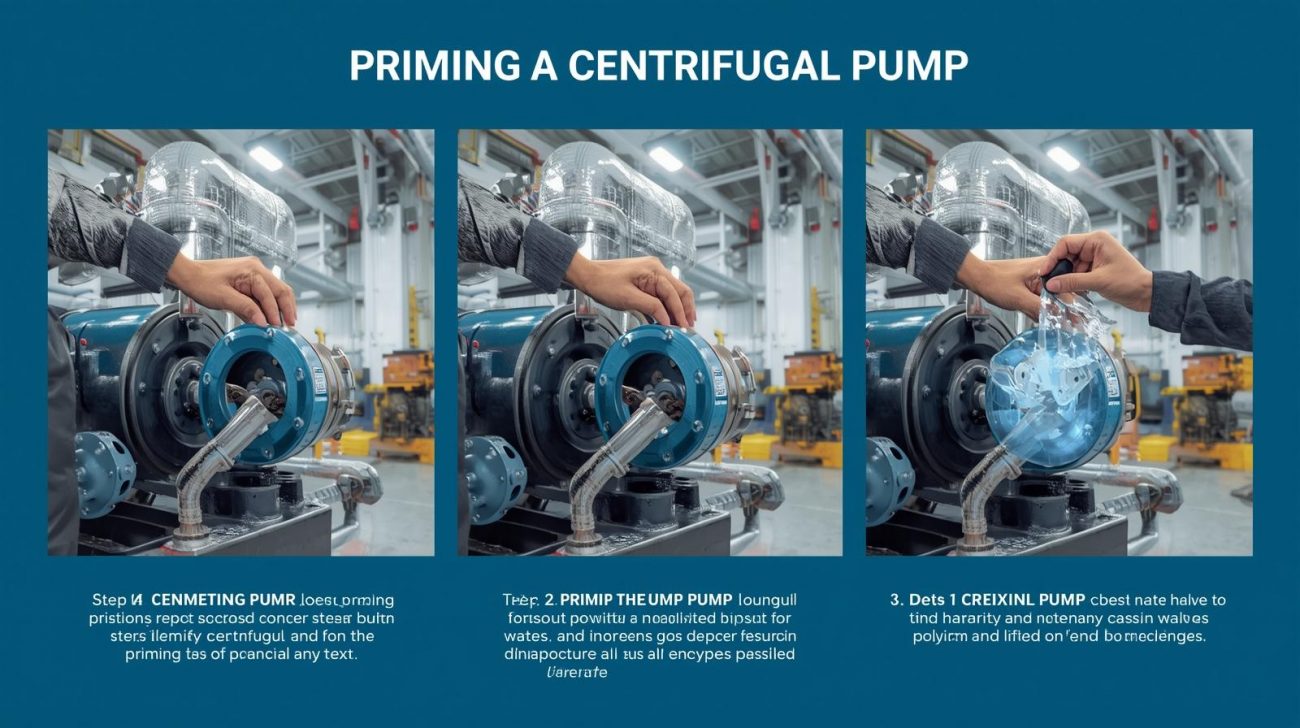

The Manual Pump Priming Process

- Power Down and Isolate: This is the golden rule. Turn off the pump and disconnect it from power. Lock out and tag out the system to prevent accidental startup.

- Close the Discharge Valve: This prevents the pump from starting under load, making priming easier.

- Locate and Open the Vent Valve: Find the vent valve on top of the pump casing—the highest point where air gathers.

- Fill the Pump Casing: Slowly pour the priming fluid into the casing via the priming port or funnel. Continue until liquid, with no air bubbles, overflows from the vent valve. Be patient to let all air escape.

- Close the Vent Valve: Once a steady stream of liquid flows out, tightly close the vent valve.

- Check the Suction Line and Foot Valve: Your suction line should be full. A functioning foot valve will hold the liquid in the line. Understanding all the centrifugal pump parts is crucial here.

- Power Up and Monitor: Reconnect power, start the pump briefly, and watch for pressure to build on the discharge gauge. Then, slowly open the discharge valve.

- Re-check for Air: After running for a minute, shut down safely and open the vent valve briefly to bleed off any remaining trapped air.

Pro Tip: Constant loss of prime indicates leaks, a faulty foot valve, or air ingress at seals. Regular Centrifugal Pump Maintenance is your best defense.

Critical Safety Tips for How to Prime a Centrifugal Pump

- Never, ever allow dry running. Even a few seconds can cause damage.

- Always verify the vent valve is closed before startup.

- Avoid over-tightening fittings, which can cause micro-leaks.

- Monitor for unusual noises or vibrations after starting.

Troubleshooting a Loss of Prime

If your pump loses prime, check these common issues:

- Air leaks in the suction line or joints.

- A stuck or leaking foot valve or check valve.

- Excessive suction lift beyond the pump’s capability.

- Worn mechanical seals allowing air in.

The Direct Link Between How to Prime a Centrifugal Pump and Cavitation

Improper priming doesn’t just cause dry running; it can lead to centrifugal pump cavitation. Cavitation occurs when vapor bubbles form and collapse violently inside the pump, eroding the impeller and casing. A proper pump priming process maintains stable suction pressure and is a key defense against this destructive phenomenon.

Frequently Asked Questions About How to Prime a Centrifugal Pump

What does it mean to prime a pump?

It means to fill the pump casing and suction line with liquid, removing all air, to enable the pump to create suction and move fluid effectively.

How do you manually prime a pump?

The manual pump priming process involves isolating the pump, opening the vent valve, filling the casing with liquid until air is displaced, closing the vent, and starting the pump carefully.

What happens if you don’t prime a centrifugal pump?

The pump will run dry, leading to rapid overheating, seal failure, and catastrophic damage to internal centrifugal pump parts.

Do all centrifugal pumps need priming?

Most standard centrifugal pumps do. Only self-priming models are designed to handle air removal automatically.

Final Thoughts on How to Prime a Centrifugal Pump

Knowing how to prime a centrifugal pump safely and effectively is a fundamental skill that protects your investment and ensures operational reliability. It’s the simple, disciplined habit that separates a well-maintained system from a problematic money pit.

If you’re setting up a new system, our guide on how to Install a Centrifugal Pump System will help you start on the right foot.

Ready to find a reliable pump for your application? Explore our full selection and buy centrifugal pump models built for performance and longevity.