Types of Centrifugal Pumps: Applications and Real-World Experience

Introduction: Hands-On Experience with Centrifugal Pump Varieties

Types of centrifugal pumps have been fundamental to my work as an industrial engineer specializing in fluid systems across American manufacturing facilities. Through years of field experience, I’ve learned that choosing the right types of centrifugal pumps isn’t just about specifications—it’s about understanding how each design performs in real-world conditions. The various types of centrifugal pumps each have distinct operational characteristics that make them suitable for specific applications, and recognizing these practical differences has been crucial to successful project implementations.

Having specified and maintained numerous centrifugal pump designs throughout my career, I’ve developed a practical understanding of how each type behaves under different operational conditions. From understanding the fundamental centrifugal pump parts to implementing comprehensive Centrifugal Pump Maintenance programs, I’ve seen how proper selection impacts operational efficiency. This guide shares the insights gained from hands-on experience with these essential industrial workhorses.

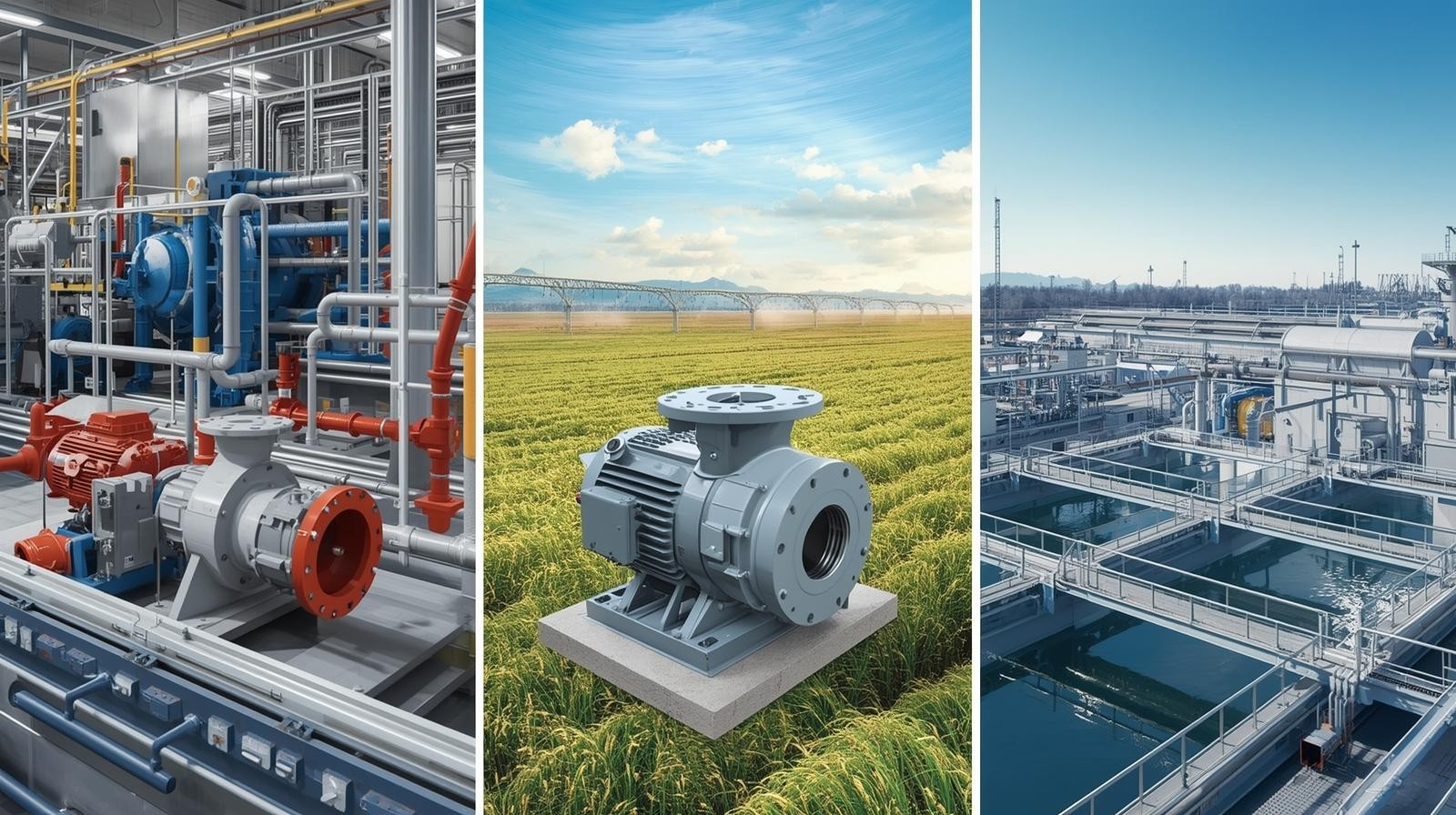

Single-Stage vs Multi-Stage Centrifugal Pumps: Practical Applications

Single-Stage Centrifugal Pumps: The Workhorse of American Industry

In my experience maintaining water treatment facilities, single-stage centrifugal pumps have proven incredibly reliable for moderate-pressure applications. These types of centrifugal pumps feature a straightforward design with one impeller, making them ideal for applications where simplicity and ease of maintenance are priorities. Understanding the complete centrifugal pump parts in these simpler designs allows maintenance teams to perform repairs more efficiently, significantly reducing operational costs over the pump’s lifecycle.

The practical advantage of single-stage centrifugal pump designs lies in their accessibility for maintenance. I recall an instance at a Midwest manufacturing plant where we replaced complex multi-stage units with Saer Centrifugal CMP79-1 HP models for their cooling water circulation. The result was a 30% reduction in maintenance downtime while maintaining adequate pressure for their heat exchangers. For smaller applications, the Saer Centrifugal CMP76-0.75HP has consistently delivered reliable performance in commercial building systems.

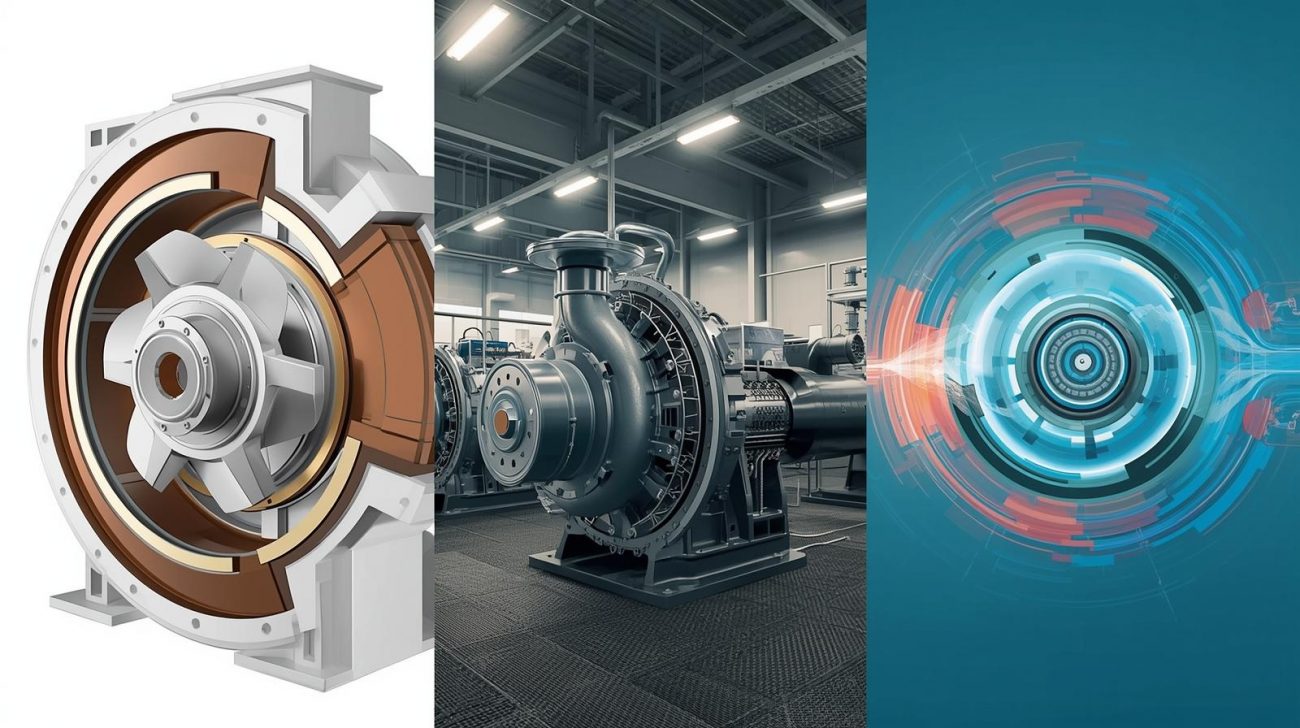

Multi-Stage Centrifugal Pumps: Powering High-Pressure Applications

My work with high-rise building systems and industrial boiler feeds has demonstrated the indispensable role of multi-stage centrifugal pumps in high-pressure applications. These sophisticated types of centrifugal pumps contain multiple impellers arranged in series, each stage progressively increasing the discharge pressure. Learning how to choose a centrifugal pump with the correct number of stages is crucial for optimizing both performance and energy efficiency.

The practical consideration with multi-stage centrifugal pump installations involves careful monitoring of performance characteristics. During a project at a Western chemical processing plant, we utilized Saer Centrifugal 6BP-9-150-4HP-220-380V Three Phase pumps for their high-pressure cleaning systems. Regular analysis of Centrifugal Pump Curves helped us identify wear patterns before efficiency degradation became significant. For single-phase power applications, the Saer Centrifugal 6BP-9-150-4HP-220V Single Phase provides similar high-pressure capabilities where three-phase power isn’t available.

Specialized Centrifugal Pump Applications and Field Experience

Self-Priming Centrifugal Pumps: Emergency and Mobile Solutions

My experience with self-priming centrifugal pumps has primarily involved construction sites, agricultural applications, and emergency response scenarios. These specialized types of centrifugal pumps eliminate the need for manual priming, making them invaluable when quick deployment is essential. Understanding both automatic and manual how to prime a centrifugal pump procedures remains essential knowledge for operators, even with self-priming models.

The practical benefit of self-priming centrifugal pump technology became particularly evident during a manufacturing plant renovation where temporary pumping solutions were required. We installed multiple Saer Centrifugal 6BP-7-109-3HP-230V units that handled varying water levels without intervention from operations staff. These pumps demonstrated exceptional reliability while requiring minimal Centrifugal Pump Maintenance, making them ideal for temporary installations and emergency applications.

Submersible Centrifugal Pumps: Subsurface Reliability

Throughout my career managing wastewater treatment facilities and municipal water systems, submersible centrifugal pumps have demonstrated exceptional reliability in challenging environments. These completely submerged types of centrifugal pumps operate with remarkable efficiency while being protected from external elements. Proper Install a Centrifugal Pump System procedures are particularly critical for submersible units to ensure long-term reliability and prevent premature failures.

The hands-on experience with submersible centrifugal pump maintenance has taught me the importance of proper installation and periodic inspection. During a recent upgrade at a municipal wastewater plant, we implemented a rigorous monitoring program that included regular checks for centrifugal pump cavitation and seal integrity. This preventive approach, combined with understanding proper centrifugal pump troubleshooting techniques, has significantly reduced unexpected failures in critical applications.

Comparative Analysis: Centrifugal Pump Applications Guide

| Pump Type | Best Applications | Pressure Range | Efficiency | Maintenance Requirements | Real-World Example |

|---|---|---|---|---|---|

| Single-Stage | Water circulation, transfer applications, irrigation | Low to moderate (up to 150 psi) | Good for low-head applications | Minimal; easy access to components | Saer CMP76-0.75HP: Perfect for small commercial building HVAC systems |

| Multi-Stage | High-rise water supply, boiler feed, pressure washing | High (150-1000+ psi) | Excellent at high pressures | Moderate; requires disassembly | Saer 6BP-9-150-4HP: Ideal for industrial cleaning systems |

| Self-Priming | Construction dewatering, agricultural irrigation, emergency response | Low to moderate | Good, with priming convenience | Low; accessible components | Saer 6BP-7-109-3HP: Excellent for temporary installation sites |

| Submersible | Wells, wastewater, flood control | Varies by design | Very good when submerged | Higher; requires extraction | Deep well applications in rural water systems |

Practical Installation and Maintenance Insights

Based on my field experience, proper Install a Centrifugal Pump System procedures significantly impact long-term reliability and performance. I’ve developed installation protocols that emphasize foundation stability, proper alignment, and appropriate piping configurations to minimize stress on pump components. These practices have consistently resulted in extended equipment lifespan and reduced maintenance interventions across multiple industrial settings.

The most valuable lesson from my hands-on work with various types of centrifugal pumps involves the critical relationship between operational practices and equipment longevity. Implementing comprehensive Centrifugal Pump Maintenance schedules that include regular performance monitoring, vibration analysis, and seal inspections has proven more cost-effective than reactive repair approaches. Understanding centrifugal pump troubleshooting techniques enables maintenance teams to address minor issues before they escalate into major failures, significantly reducing downtime and repair costs.

Conclusion: Selecting the Right Pump for Your Application

Through years of practical experience with different types of centrifugal pumps, I’ve learned that successful pump selection balances technical specifications with real-world operational requirements. The process of learning how to choose a centrifugal pump involves understanding both the immediate application needs and long-term maintenance considerations. By understanding these practical differences and implementing appropriate maintenance practices, industrial facilities can optimize their pumping systems for reliability, efficiency, and long-term performance.

Frequently Asked Questions

What are the most reliable types of centrifugal pumps for continuous operation?

Based on my experience, single-stage centrifugal pumps generally offer the best reliability for continuous operation in standard applications, while multi-stage designs provide superior performance in high-pressure continuous operations. Understanding centrifugal pump curves helps identify the optimal pump for specific continuous operation requirements.

How do I prevent common issues with different types of centrifugal pumps?

Regular maintenance focusing on centrifugal pump cavitation prevention, proper alignment, and seal integrity is crucial. Understanding centrifugal pump troubleshooting techniques helps identify issues early, while comprehensive Centrifugal Pump Maintenance prevents most common problems.

What factors should I consider when choosing between centrifugal pump types?

Consider operating pressure, fluid characteristics, installation environment, maintenance accessibility, and operational requirements. Reviewing centrifugal pump curves for each specific model provides valuable performance insights, and understanding basic centrifugal pump parts helps assess maintenance complexity.

Can I convert between different types of centrifugal pumps in an existing system?

While possible, such conversions require careful analysis of system requirements and may involve modifications to piping, foundations, and electrical systems. Professional assessment is recommended before making such changes, and proper Install a Centrifugal Pump System procedures must be followed to ensure optimal performance.