Your Essential Centrifugal Pump Maintenance Checklist

In the world of fluid dynamics, few pieces of equipment are as fundamental and hardworking as industrial pumps. These powerful machines, the core of many systems, are a type of Centrifugal Pumps that operate tirelessly behind the scenes. However, when they fail, the consequences—costly downtime, production halts, and emergency repairs—are immediately felt. When faced with a sudden breakdown, the first step is often Troubleshooting Common Centrifugal Pump Problems, but a proactive approach can prevent these issues entirely.

The journey to a reliable system begins even before installation; you must first Choose a Centrifugal Pump that is correctly sized and suited for your application. Once installed, its longevity and performance depend on a robust, experience-based maintenance strategy. This article provides the ultimate centrifugal pump maintenance checklist to ensure your equipment runs efficiently for years to come.

What is Preventive Maintenance? A Core Concept in Your Centrifugal Pump Maintenance Checklist

Before diving into the checklist, we must define our strategy. Preventive maintenance is a proactive methodology focused on scheduled inspections and service tasks designed to identify and rectify potential issues before they cause a failure. This is the opposite of reactive maintenance (fixing things after they break). A well-designed pump preventive maintenance plan is the single most effective way to avoid the common causes of pump failure and extend the life of your assets.

The Ultimate Centrifugal Pump Maintenance Checklist: From Daily to Annual Tasks

This checklist is structured by frequency, providing a clear and actionable schedule for your maintenance teams.

Daily Inspections: The First Step in Your Centrifugal Pump Maintenance Checklist

These are quick, sensory checks that form the foundation of your daily pump inspection routine. They can often detect the early signs of excessive pump vibration or other serious issues.

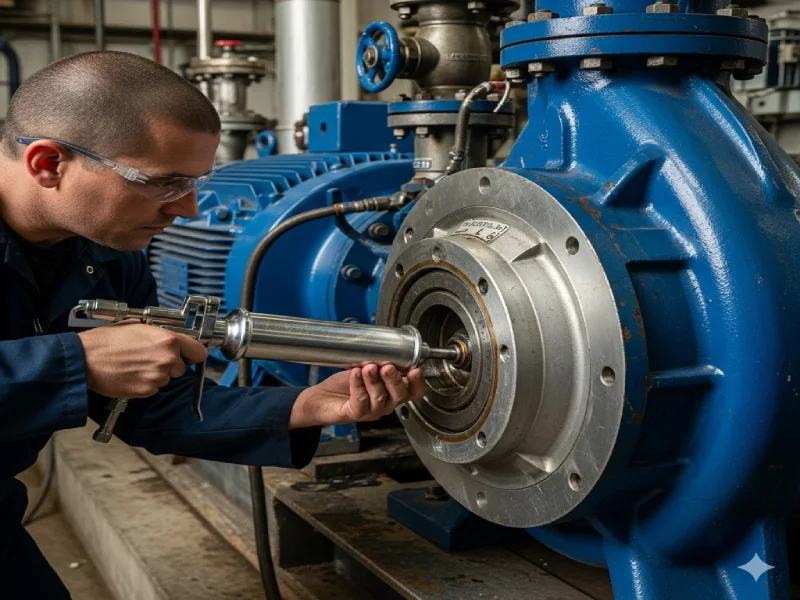

- Leak Detection: Visually inspect the mechanical seal area, casing gaskets, and pipe flanges. A dripping seal is a clear warning sign.

- Noise and Vibration: Listen for abnormal sounds like grinding, rattling, or cavitation noise. A smooth, consistent hum is the sign of a healthy pump.

- Bearing Temperature: Use a non-contact infrared thermometer to check the bearing housing temperature. A sharp increase is a primary indicator of

pump overheating causesrelated to lubrication failure or wear. - Pressure Gauge Monitoring: Check suction and discharge pressure readings. Deviations can indicate a blockage, cavitation, or a problem elsewhere in the system. This data helps ensure the pump is operating correctly on its Centrifugal Pump Curves.

Weekly Checks: A Key Part of Your Centrifugal Pump Maintenance Checklist

These weekly pump checks build upon the daily routine with a slightly more hands-on approach.

- Lubricant Levels: Check the oil level and clarity in the bearing housing sight glass. Cloudy or low oil requires immediate attention.

- Area Cleanliness: Ensure the pump and motor are free of dust, debris, and process fluid residue. A clean pump dissipates heat more effectively.

Monthly Tasks: A Deeper Dive in the Centrifugal Pump Maintenance Checklist

These monthly tasks require basic tools and a closer look at the pump’s operational health.

- Bearing Lubrication: For grease-lubricated bearings, follow the manufacturer’s Lubrication Schedule. Crucially, avoid over-greasing, which can blow out bearing seals and cause overheating.

- Foundation Integrity: Check and tighten the mounting bolts for both the pump and the motor. A loose foundation is a major source of vibration and misalignment.

- Motor Health Check: Use a clamp-on Ammeter to measure the motor’s current draw. Compare it to the nameplate data. Higher-than-normal amps can signal hydraulic issues or increased mechanical friction.

Quarterly Maintenance: Advanced Diagnostics in Your Centrifugal Pump Maintenance Checklist

During quarterly pump maintenance, we move into predictive diagnostics.

- Vibration Analysis: This is the most critical task. A trained technician using Vibration Analysis equipment can detect bearing defects, imbalance, resonance, and misalignment long before they become catastrophic. This data is key to a

pump bearing failure analysis. - Coupling Alignment: Verify the coupling alignment. Even minor misalignment drastically increases the load on bearings and seals. For precision, Laser Alignment is the industry standard and highly recommended.

Annual Overhaul: The Comprehensive Centrifugal Pump Maintenance Checklist

The annual pump overhaul is a complete teardown during a planned shutdown.

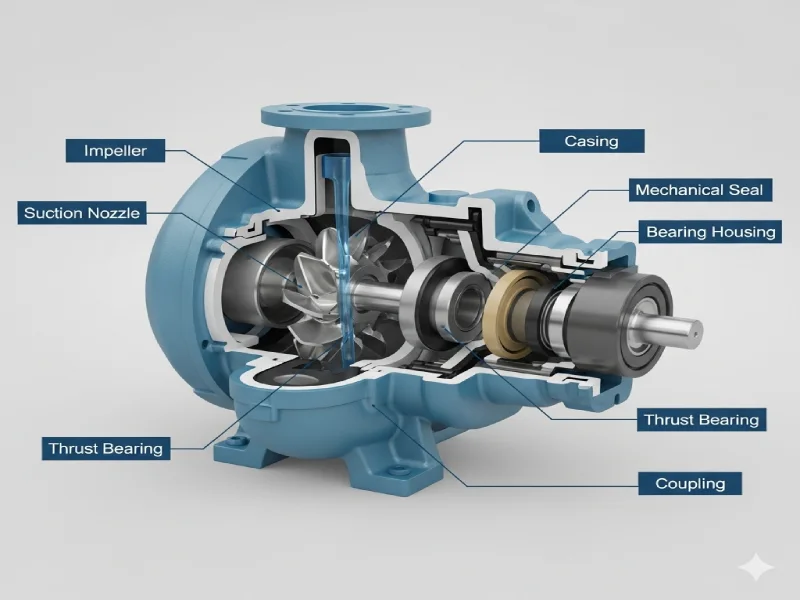

- Complete Disassembly: A full teardown allows for a detailed inspection of all Centrifugal Pump Parts & Functions, including a thorough

pump impeller inspectionfor wear or erosion and apump casing maintenancecheck for corrosion. - Component Replacement: Automatically replace all bearings, gaskets, and O-rings. Perform a detailed Mechanical Seal Inspection and replace it. Attempting a

leaking mechanical seal repairon a unit that has been in service for a year is often not cost-effective. - Motor Servicing: The

pump motor maintenanceshould include electrical testing, cleaning, and bearing replacement by a qualified shop.

Technical Deep Dive: Key Focus Areas of the Centrifugal Pump Maintenance Checklist

For specialists, understanding why certain tasks are critical is key to effective maintenance.

Coupling Alignment: A Vital Part of Any Centrifugal Pump Maintenance Checklist

Why is pump alignment important? Misalignment forces the shafts to flex with every rotation, inducing cyclic fatigue stress on the bearings. This leads to premature bearing failure, seal leaks, and increased power consumption. Laser Alignment is superior to older methods because it provides quantifiable, repeatable results down to a thousandth of an inch.

Vibration Analysis: A Predictive Centrifugal Pump Maintenance Checklist Tool

Vibration Analysis is like an EKG for your pump. It measures the frequency and amplitude of vibrations, creating a unique signature. By trending this data over time, analysts can pinpoint developing issues:

- High-frequency vibration often points to early-stage bearing wear.

- Vibration at the pump’s running speed (1x) usually indicates imbalance.

- Vibration at twice the running speed (2x) is a classic sign of misalignment.

Answering Your Questions: FAQ for the Centrifugal Pump Maintenance Checklist

What is the maintenance of a centrifugal pump?

It is a scheduled, proactive program of inspection, lubrication, testing, and component replacement aimed at maximizing reliability and preventing unplanned downtime.

How often should you grease a pump?

This depends entirely on the pump’s speed, bearing size, operating temperature, and environment. Always follow the manufacturer’s Lubrication Schedule. If one isn’t available, monthly is a safe starting point for standard applications, but this should be refined based on analysis.

How do you check a pump for proper operation?

You check performance by verifying that its key parameters—pressure, flow rate, and power consumption (amps)—match the manufacturer’s performance curve for the current operating conditions. This is supplemented by sensory checks for abnormal noise, vibration, and temperature.

Need professional assistance with your centrifugal pump maintenance program or in-depth troubleshooting? Contact the expert team at SpringPump for comprehensive service and support.