Description

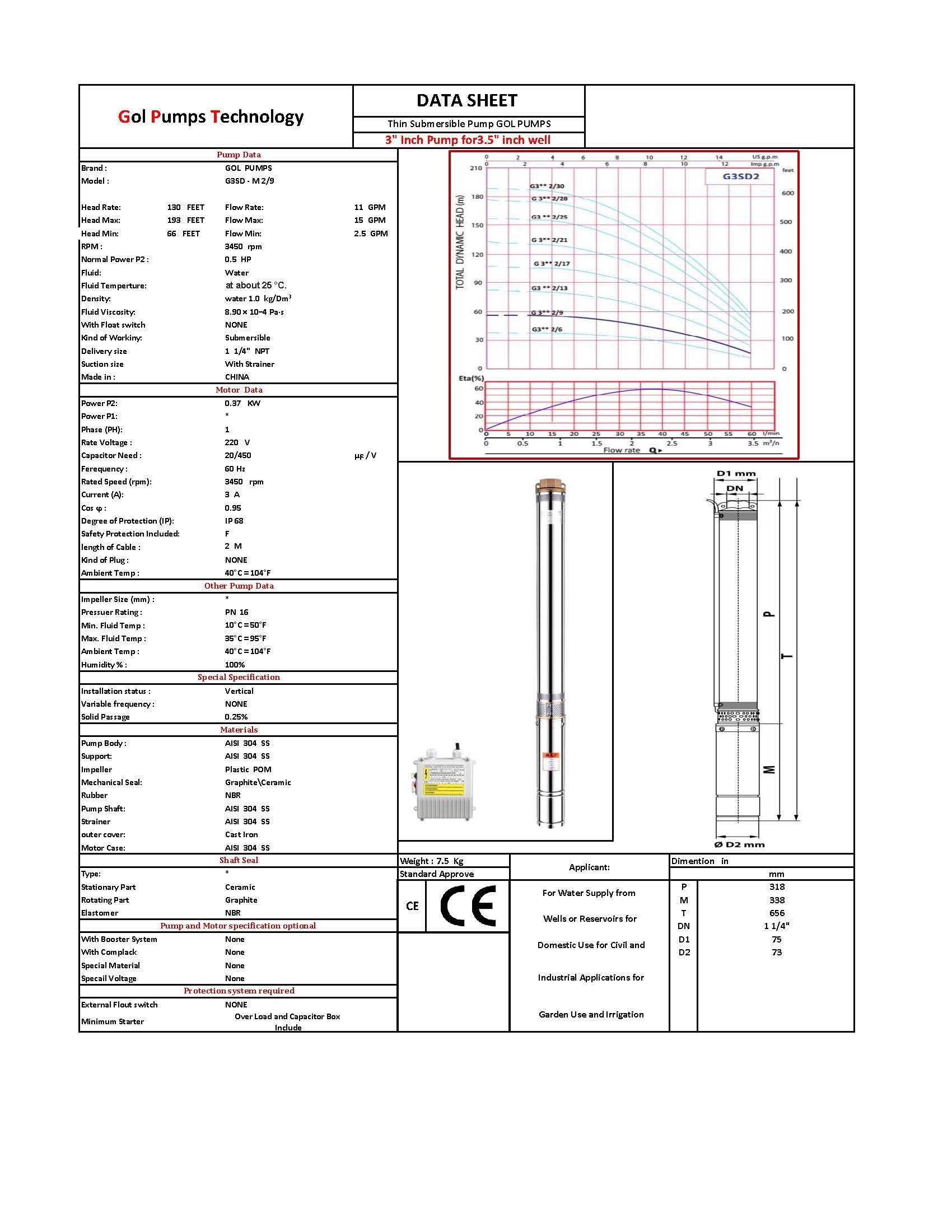

This 3″ thin submersible pump from GOL Pumps can be used for water supply in wells and reservoirs. It can reach up to 193 feet of head and is a great fit for 3.5″ diameter wells.

- Water supply from wells and reservoirs

- Comes with a control box

- Rewindable motor

Applications

- For water supply from wells or reservoirs

- For domestic use

- for civil and industrial applications

- For garden use and irrigation

Operating conditions

- Maximum fluid temperature up to 95°F

- Maximum sand content: 0.25%

- Minimum well diameter: 3″

Motor and Pump

- Rewindable motor

- Single-phase:110V/60Hz or 220V/60Hz

- Equip with start control box or digital auto-control box Pumps are designed by casing stressed Curve tolerance according to ISO 9906

Technical Specifications

Pump Type Thin Submersible Pump Pump Brand GOL Pumps Pump Model 3SDM0 2/9 Warranty 1 Year Maximum Head 193ft Minimum Head 66ft Maximum Flow 942 GPH Minimum Fluid Temperature 50°F Maximum Fluid Temperature 95°F Maximum Ambient Temperature 104°F Discharge 1.25″ NPT Pump Material Stainless Steel 304 Pump Diameter 3″

Reviews

There are no reviews yet.